Products

From cloud-based PLC project management to version control, factory-wide visibility, and industrial cybersecurity, our products are built to solve the real challenges engineers and maintenance teams face every day.

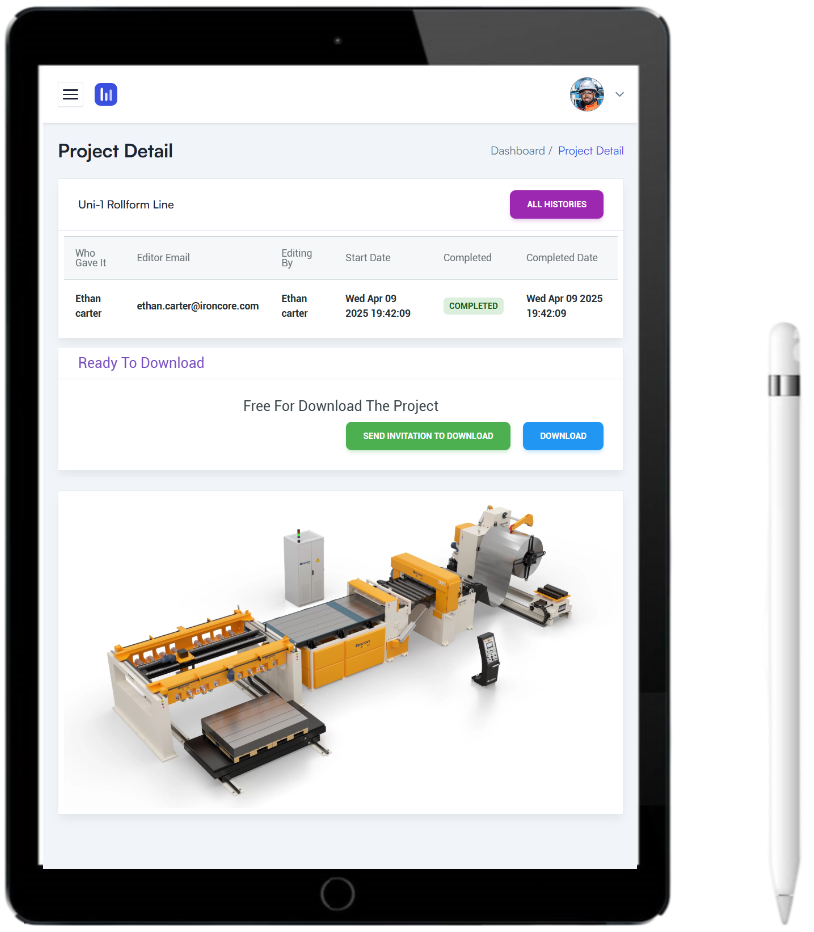

Centralize your plant’s PLC and HMI projects in a secure cloud workspace. Stop chasing folders and outdated copies—work from a single source of truth, enforce edit-locks, and keep a complete audit trail for every change.

Track your PLC projects end-to-end

From shop-floor to cloud, PLCProject keeps projects structured by line, machine, and asset. Assign ownership, lock edits while someone is working, and reopen access automatically when the latest version is uploaded. Version history lets you review, compare, and roll back in seconds—so maintenance teams always start from the right file.

Features

Our PLC Training Web Application is a dedicated online platform for factory maintenance staff. It provides continuous PLC training, tracks employee progress, and ensures up-to-date knowledge for improved efficiency and reduced downtime.

PLC Training Web Application

Our PLC Training Web Application is designed for anyone who wants to build a career in industrial automation. From factory maintenance staff to aspiring automation engineers, the platform offers continuous PLC training, tracks learning progress, and ensures up-to-date skills for a stronger future in automation.

Features

Boost production quality with real-time tracking and reporting.

Complete projects on time

Our Quality Tracking System, helps manufacturers maintain world-class standards. With instant monitoring, detailed reporting, and traceable records, it ensures consistent quality across every production stage—minimizing downtime and maximizing efficiency.

From assembly to final inspection, the system captures, organizes, and analyzes quality data in real time. Teams can log inspections, flag defects, and access instant reports, making it easier to take corrective actions quickly. With full traceability and historical data at your fingertips, long-term process improvements become simple and effective.